There is something special about the printing method that is letterpress. Brief affairs between the very real metal type and beautiful uncoated stock produce children of tangibility, each slightly different, but always of the same family. A thinly veiled process that gives any piece of design extra warmth and comfort, metal type was the norm from Gutenberg through to only a few decades past. Through a stroke of good luck I’ve managed to get a 1930s designed Heidelberg into my garage.

Friday

Oh, by the way, you’re getting your press tomorrow. This simple email from my wife was by far one of the best I’ve ever received. I now knew for certain that the following day I would have a large track backing into the drive way, to deliver something I’d fallen in love with; a piece of engineered beauty—a Heidelberg Flywheel Platen Press.

Naturally, I was so excited that I shared this little piece of information with the whole studio and spent the rest of the afternoon thinking of what my plans were for my new toy, while working through changes to jobs and anxiously drinking copious amounts of coffee and water, waiting for the day to come to its end.

How it Happened

I didn’t go looking for this press. I wasn’t looking for any type of press really. The 2 tonne machine just fell into my lap. I married into a family of printers. My wife and her family run a printing business—something that made introductions easier. To make a long story short, in the pursuit of expanding their business, they’ve recently bought out another printing business and effectively doubled their list of equipment. In their list of machinery was now two of these presses, when they only need one (mostly for die cutting and numbering), so instead of it taking up space in their shed, we gave it a home in the garage.

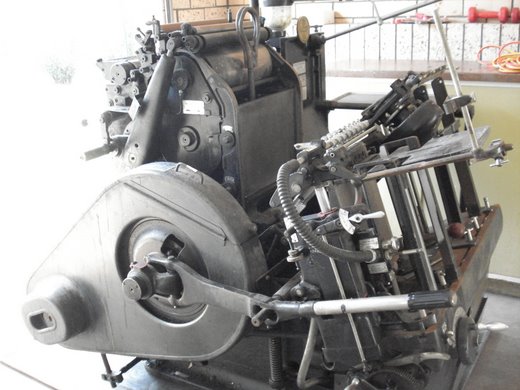

The Heidelberg “Windmill” Platen Press

The moniker Windmill comes from the way the paper-gripper rotates when moving paper through the press. Two arms rotate as they pick up a sheet of paper on the left, drop it in the middle to be impressed by the inked type, to be picked up again and dropped off on the right.

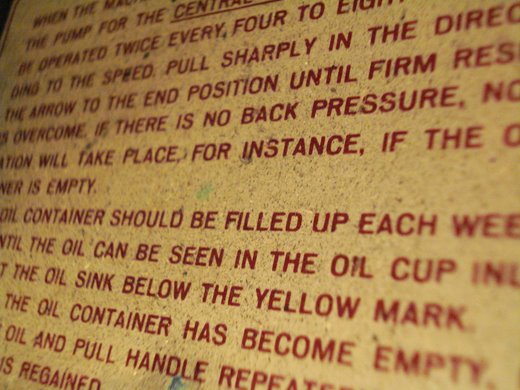

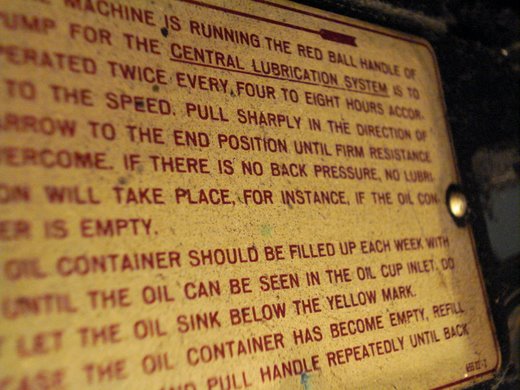

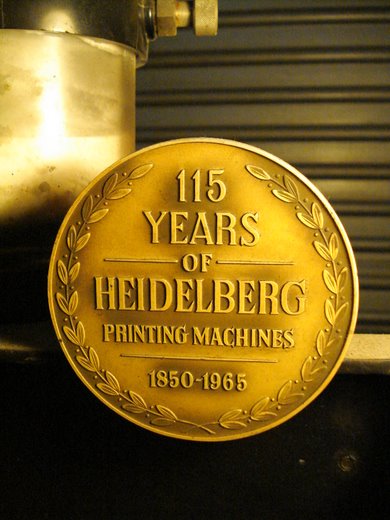

Heidelberg built around 250,000 of these machines over a 30-odd year span, ending in the 70s. Going by a serial number on the front of the press, this was was manufactured towards the end of the run, in 1967. Unlike most mechanical things you buy, a Heidelberg press isn’t one you need to worry about. As long as they are kept well oiled and fairly clean they’ll keep on going, making impression after impression.

Saturday

Saturday morning rolls around and I’m reminded that my wife’s father, the truck/crane and the press will be arriving sometime soon. We clean up the garage, have some breakfast, move the car and wait while watching some awful Saturday morning television.

Around 11, things start to happen. We get a phone call to let us know they are on their way. Not long after this, a truck wider than our house shows up and the fun starts. Doug (the truck & crane guy) steps out of his truck and introductions and pleasantries are exchanged. A few moments later, he hops back into his truck and backs it into our driveway, right up to within a couple of meters of our garage.

A few moments later and the press is unchained and floating through the air—I don’t know why, but 2 tonnes of flying metal is a rather intimidating sight. Ten minutes after it initially goes airborne off the back of the truck, it finds its feet back on the ground. Now the tricky bit – getting it into the garage.

but looked to be in great condition

German-engineered printing brilliance!

Into the Garage

We had two problems – the crane was too tall for our garage door, and we have a slight lip, or step up, into our garage. Nothing devastating really, only a few inches, but something that was going to make things a little tricky. Doug the driver raised the press a few inches again and backed the whole truck up a few more feet, getting with intense inches of going straight through the top of the garage door.

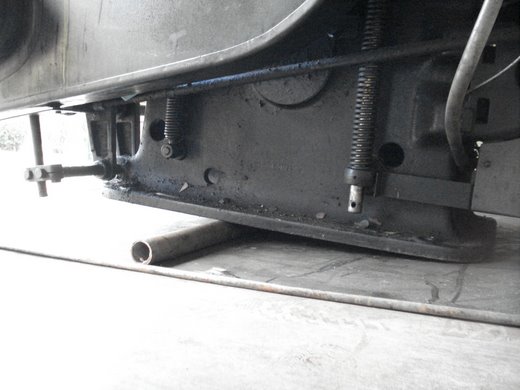

We put some steel pipes down and Doug lowered the press. The hook of the crane was removed and the moment I had been wondering (read that as “worrying”) about all morning had arrived. While I trust my father in law, his assurance of “we’ll just roll it in” had me a little nervous. The idea of just rolling it in seemed a little too easy. This thing can hit full-colour registration—it’s too delicate to just be rolled around on impromptu rails! Ok, so I was thinking a little too preciously … turns out, all we had to was “roll it in”.

as the garage door and if it wasn’t for some careful maneuvering,

could have ended badly

was all that was holding up the press in mid-air

With two pipes under the press, it was easily pushed up to the garage door and the infernal lip. Because of the garage being about two inches higher than the driveway, a slightly smaller pipe was place onto the drip dray, with the hope of just being able to roll it straight onto the new, smaller, roller. Turns out it wasn’t quite as simple as that. Rocking the whole press back and forth on the axis of one of the first pipes, while pushing it forward, we managed to get it partly into the garage and up onto the roller on the drip tray.

Now that it was on the drip-tray, it was easily rolled into position. It was then rocked forwards so the front roller could be removed – no problem here at all. With the front of the press in place, the front was lifted with a (very large) metal stake and the front pipe removed. With a rather loud THUD, the stake was removed and the press fell into place. So much for my allusions of a delicate piece of machinery. The steal loop that the cranes hook clipped into is unbolted and removed and the press is welcomed to its new home.

to remove the other second pipe

Tags

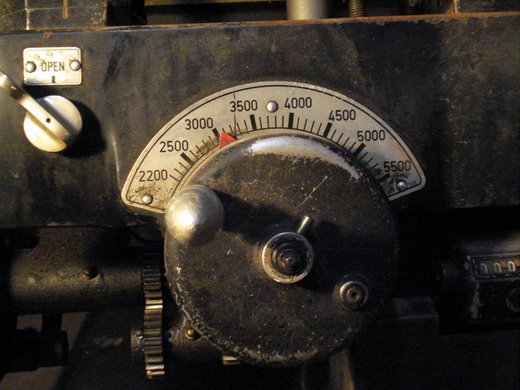

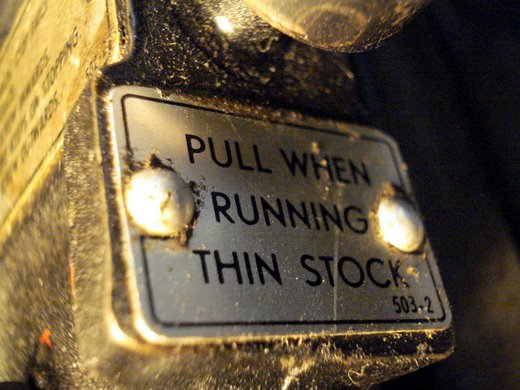

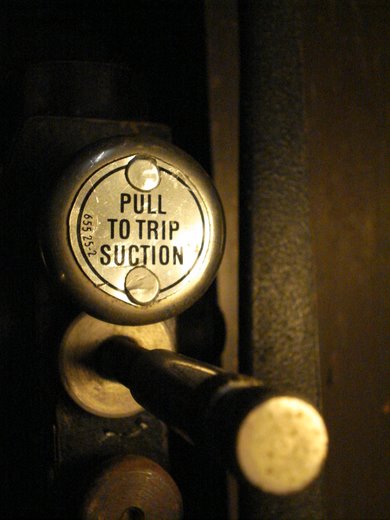

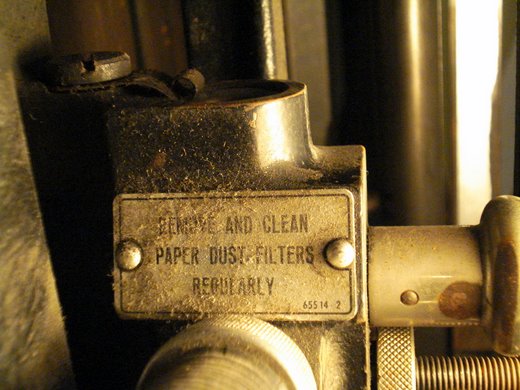

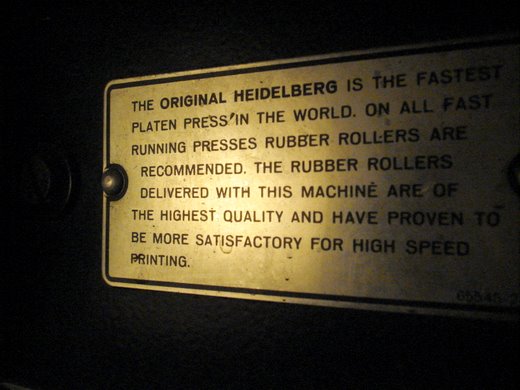

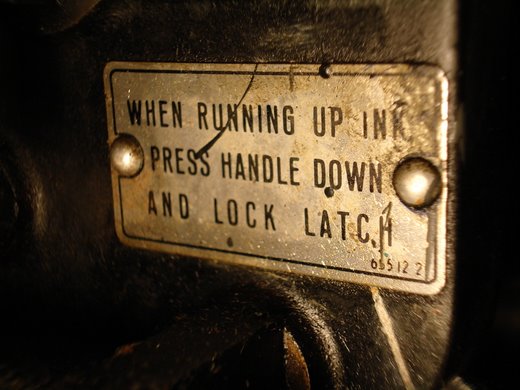

One thing I really want to mention are the tags, which are all over the press. There are little notes and reminders found everywhere. From instructions such as “Pull to stop suction” to stop the vacuum that picks up the paper being lifted to be grabbed by the Windmill, to reminders like “Remove and clean paper dust filters regularly” and “Let air escape when pressure is too high,” there is just something about the humanness of this press that I love.

Plans

The press has a couple of hills for me to get over. It needs to be cleaned—really cleaned. While presses aren’t meant to be the epitome of cleanliness, this one is downright rotten. It also needs a different motor as the current one is 3-phase, when our only options is 2 phase (Not that I fully understand it all, something about 3 being being like 2 phase, but with plus-one ka-pow). A couple of the rollers are a little rusty, so a little TLC with some super-fine sand paper is needed before it spreads. And the biggest hurdle? I need to learn to tame the beast. This one I’m not too worried about, as between my family, the previous press man who ran it and the immense wealth and passion that is scattered across the web, I’m sure it’ll be nothing but an enjoyable experience.

Some of my more grandiose plans:

- Buy at least four sets of fonts

- Build California Type Cases for all fonts I end up with

- Buy some wood type

- Print a small book of lyrics (I’m thinking Led Zeppelin) to help me learn how to use the press

- Make a digital font analogue. So many of our beloved fonts started out as metal—I’d love to take a beautiful font that has never been physical, and cut it by hand. Stay tuned for a while to see this one happen.

- Write a series of articles related to letterpress, from cleaning this press, how it works and how far it can be pushed into craft and artistic realms through to Linotype, other letterpresses and the current revival of this craft.

Linotype

Luckily my wife and her family discovered something that I wasn’t told about till the press arrived. The print business they purchased use to have a Linotype machine, which we knew about through discussions with the previous owners, as well as finding a (parts) manual for it. I looked all over, but couldn’t find any old sticks of type. Turns out it was because it was found and hidden from me, before I got there, to be handed over as a surprise at some point down the road. Much to my glee, it’s now sitting in our garage, next to the press. It’s nothing overly interesting content wise as it appears to be things like bus timetables and membership forms. Not super-exciting, but perfect to use while learning and writing a couple of the above mentioned articles.

I’ve been noticing such a love for these types of machines and this technology lately, that I thought some people might find this story interesting. I’m planing on taking you on the journey of discovery this machine will take us, so that we can learn about this great piece of typographic and print history together. Over the next month or so I plan on getting the machine as clean as I can, while learning how it operates as well as scouring the internet for some fonts and knowledge.

REFERENCES & LINKS

Boxcar Press A great press shop in New York that has a great site you can get lost in easily. Including a nice little page (and a good shot) of the Heidelberg Windmill. The best find on the site? A scan of the manual which is proving to be invaluable.

Creative Curio

Lauren Marie of Creative Curio has been doing up her own press lately and has done a great job of documenting it.

Brooklyn Bookbinder

Some stunning work can be found here, as well as a great blog by Maggie Campbell, who has recently gone freelance and is sure to go very far.

Don Black Linecasting

A great video and discussion about the Heidelberg Windmill Platen, which shows the machine in action and gives a nice background on it. Red balls, black balls, it’s all beautiful!

Briar Press

A community for those who love letterpress in all its forms.

British Letterpress

Good site with a fair bit of knowledge.

Master Your Craft.

Weekly.

Become the designer you want to be.

Join a group of talented, creative, and hungry designers,

all gaining the insight that is helping them make

the best work of their lives.